3D Filament Splicer

Project cancelled, click here to read why

3D Printing is in some ways similar to personal computers of early 80es: It is revolutionary, exciting, fun and monochrome.

Our mission is to bring colors to open source 3D printing scene. Our first product on this journey is 3D Filament Splicer.

Printing in multiple colors

If you own filament based 3D Printer you can print in multiple colors, all what you need to do is join differently colored filament pieces in one string. The process is not exactly rocket science:

- Cut pieces of differently colored filament

- Heat up the ends of filament pieces

- Join them together

- Feed multi-colored filament into your printer

This can be done by hand with help of heat source such as print head of your 3D Printer or soldering iron.

Why Filament Splicer

Joining filament by hand without assistance of specialized tool is quite cumbersome process, it often produces deformed and fragile joins which can get stuck in extruder / bowden tube or snap during high stress situations such as retraction or passage through extruder drive mechanism. The later is especially true with high quality, tightly coiled filaments such as low opacity PLA from Ultimaker.

Filament Splicer considerably speeds up and eases the process of joining filament.

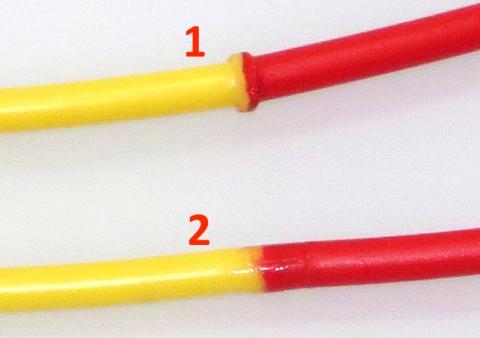

1. Filament joined by hand, join requires post processing and is likely to be fragile.

2. Filament joined by Filament Splicer, no post processing required, solid join.

Features

- Small and ergonomic footprint

- Quickly setup and pleasure to use

- Suitable for 1.75mm and 3mm filaments

- High temperature range up to 235c, suitable for PLA and ABS Filament

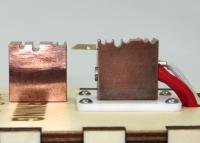

- Heater block made of pure copper with brass knife for cutting off excess filament

- Cooling block made of pure copper to quickly cool down and form joined filament

- Heat insulation PFTE parts are made of European PFTE with all appropriate certifications

- Copper parts are precisely CNC milled by our local partner company in Switzerland

- Works with 110v and 220v voltage

Usage

For small pieces of filament which can be rotated in fingers

- Hold filament pieces in both hands

- Touch heating block with filament ends for 1 second

- Join pieces in the appropriate groove on heater block

- Rotate filament ~360 degrees to remove excess plastic

- Move pieces into groove on cooling block

- Keep rotating in cooling block to ensure proper diameter

- One join takes less then 20 seconds to complete

For long pieces of filament which can not be rotated

- Hold filament pieces in both hands

- Touch heating block with filament ends for 1 second

- Join pieces in the groove on heater block

- Move pieces into groove on cooling block

- Push filament into cooling groove, so that excess plastic forms a bulge above the joint, wait for 3-5 seconds

- Remove cooled filament and use hot knife on heater block to quickly cut off excess plastic

- One join takes about 15 seconds to complete

Availability

Filament splicer can be pre-ordered from us, it is available as a DIY kit or fully assembled unit.